Safety Standards

VPROTX FOOTWEAR offers a number of safety and protection specifications. To facilitate understanding of these specifications, we use various pictograms. Below is a list of those pictograms and their meanings.

ELECTRICAL FEATURES

Safety shoes with electric shock resistant sole.These shoes pass the test required by the Canadian CSA Z-195/14standard, i.e. in a dry environment a shock of 18000 V (AC), 60Hz will be applied and must pass the test with no discharge to the ground and the current

leakage must not exceed 1.0 mA.

Their use is recommended with the aid of primary personal protection equipment (gloves, footboards or other) that will protect the user from contact with open circuits, so as to minimize the risk for the operator to suffer an electric shock. Protection can be compromised if the shoes get wet,dirty, with too worn soles or metal particles stuck in the sole. The properties of these shoes could be compromised if they are used in too humid

environments. Wearers must always check the electrical properties of the shoe before entering a risk area.

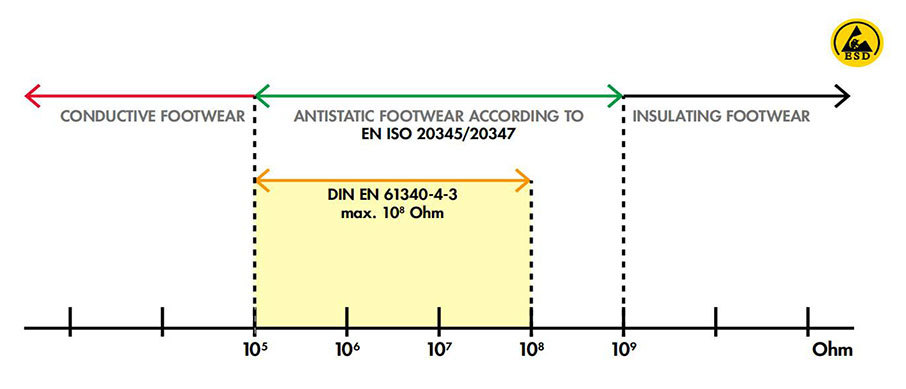

Antistatic footwear should be used if it is necessary to minimize electrostatic build-up by dissipating electrostatic charges, thus avoiding the risk of ignition of in flammable substances and vapors, for example, and if the risk of electric shock from any electrical apparatus or live parts has not been completely eliminated. It should be noted, however, that antistatic footwear does not guarantee sufficient protection against electric shock, as it only introduces electrical resistance between the foot and the floor. If the risk of electric shock has not been completely eliminated, additional measures to avoid this risk are essential. Such measures, as well as the additional tests mentioned below, should be a routine part of the accident prevention programmed at the workplace. Experience has shown that, for antistatic purposes, the discharge path through a product should normally have an electrical resistance of less than 1000 MΩ at any time throughout its useful lifetime. A value of 100 kΩ is specified as the lowest limit of resistance of a product when new, in order to ensure some limited protection against dangerous electric shock or ignition in the event of any electrical apparatus becoming defective when operating atvoltages of up to 250V. However, under certain conditions, users should be aware that the footwear might provide inadequate protection and additional provisions to protect the wearer should be taken at all times. The electrical resistance of this type of footwear may be altered significantly through fixing, contamination or moisture. This footwear will not perform its intended function if worn in wet conditions. It is therefore necessary to ensure that the product is capable of fulfilling its designed function of dissipating electrostatic charges and also of giving some protection during the whole of its lifetime. The user is recommended to conduct an electrical resistance test on the spot and use it at regular and frequent intervals. If worn for prolonged periods and in moist and wet conditions, class I footwear can absorb moisture and become conductive. If the footwear is worn in conditions where the sole material becomes contaminated, wearers should always check the electrical properties of the footwear before entering a hazard area. During use, no insulating elements should be placed between the inner sole of the footwear and the wearer’s foot; the electrical properties of the footwear/insole combination should be checked.

ESD footwear discharge static electricity and avoid damaging surrounding objects;they are designed in compliance with the following standards: IEC EN 61340-5-1:2016 - IEC EN 61340-4-3:2018 - IEC EN 61340-4-5:2018.An electro-statically charged object tends to discharge static electricity and create conditions that could damage any objects nearby. Devices sensitive to electrostatic conditions (ESD - electrostatic discharge) with low sensitivity threshold may be affected.Critical situations, where anti-static electricity shall be kept under control are the following:−if there is a possibility of triggering a free due to the presence of substances etc.);

−there could be attraction between two materials that create dangerous situationsor damages; interfere with or damage devices sensitive to electrostatic conditions.

−in the areas protected against electrostatic charges (EPA) where no object or activity carried out could cause significant damages to the devices sensitive to electrostatic conditions.

In these areas, there is a local ESD coordinator who is responsible for all the problems related to the protection of the ESD.